Understanding Brake Pads and Their Importance

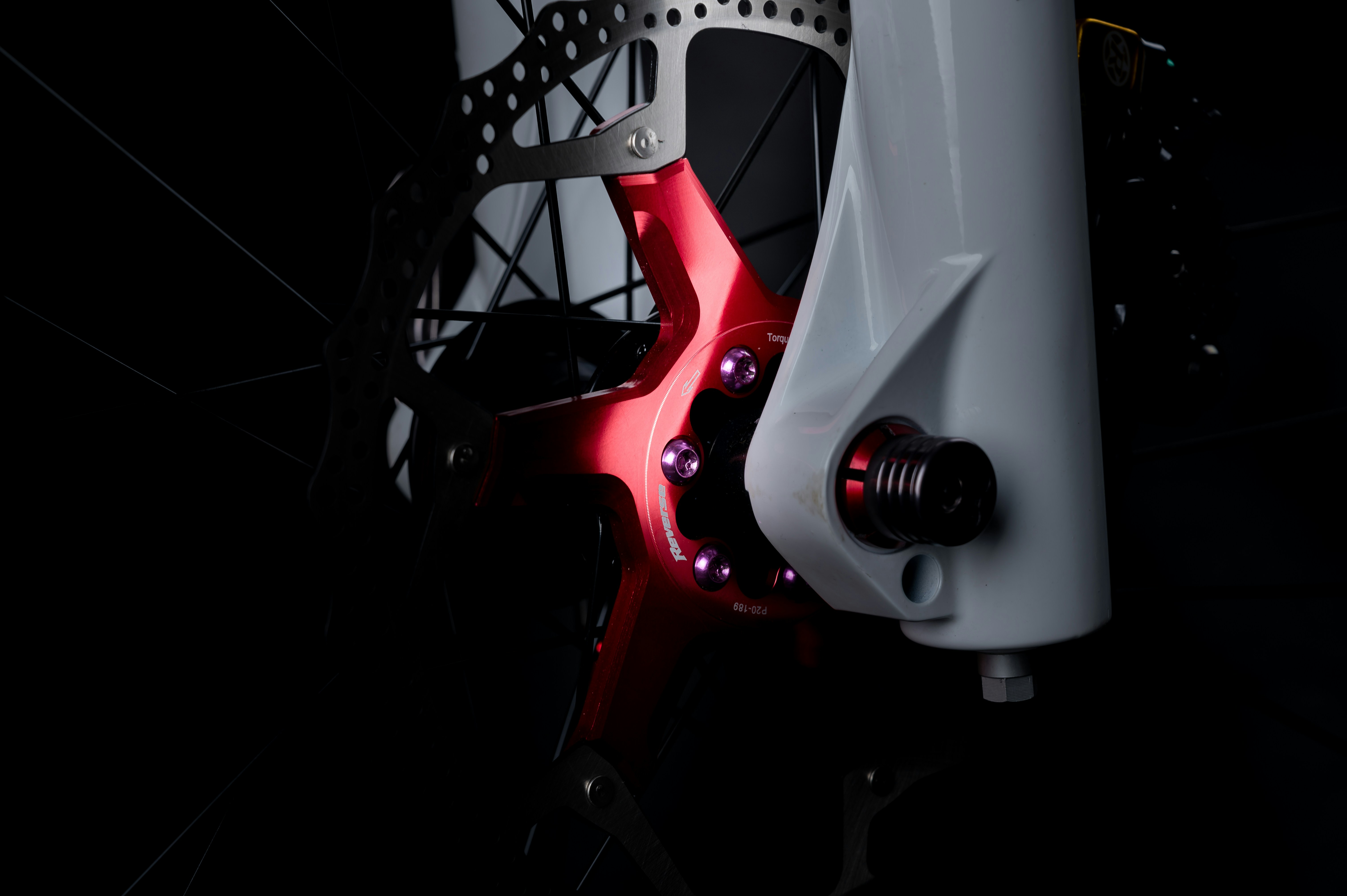

Brake pads are a vital component of a vehicle’s braking system, designed to create the necessary friction that allows the vehicle to slow down or come to a complete stop. Typically made from materials such as metal, ceramic, or organic compounds, these pads press against the brake rotor when the brakes are engaged, converting kinetic energy into thermal energy. This process is critical for ensuring vehicle safety, as it allows drivers to maintain control during operation.

The role of brake pads extends beyond merely halting the vehicle; they also contribute to the overall performance and effectiveness of the braking system. Well-maintained brake pads provide consistent stopping power, ensuring that the vehicle responds predictably in emergency situations. Conversely, worn or damaged brake pads can lead to decreased braking efficiency, which can increase stopping distances and the risk of accidents.

Regular maintenance of brake pads is crucial to avoid safety hazards. Drivers should be attentive to several key signs indicating that brake pads may need replacement. A squealing or grinding noise when braking often signals that the brake pads are worn down, as many pads are equipped with wear indicators that emit these sounds to warn the driver. Additionally, a noticeable decrease in braking responsiveness or a pulsating sensation in the brake pedal may suggest that the pads or rotors are compromised and require immediate attention.

In summary, understanding the importance of brake pads is essential for any vehicle owner. Keeping a close eye on their condition and responding promptly to warning signs can significantly enhance safety and driving performance. Regular inspections and timely replacements of brake pads are crucial not only for safety but also for the longevity of the overall braking system.

Gathering the Right Tools and Materials

Changing brake pads is a task that requires specific tools and materials to ensure it is performed efficiently and safely. Before beginning this essential automotive maintenance, it is crucial to gather the right equipment. The first thing you will need is a suitable set of brake pads. Depending on your vehicle make and model, you can choose between several types, including ceramic, semi-metallic, and organic pads. Each type offers different advantages, such as durability, braking performance, and noise levels. Understanding these options will help you select the best brake pads for your car.

In addition to the brake pads, a few basic hand tools are indispensable for this process. At a minimum, you will require a lug wrench to loosen the wheel nuts, a jack to lift the vehicle, and jack stands for safety. A socket set is needed for removing caliper bolts, while a c-clamp or brake tool will help compress the caliper piston, allowing for new pads to fit properly. Moreover, having a pair of pliers on hand may assist in removing any retaining clips or pads that are difficult to reach.

Safety equipment is equally vital for changing brake pads. A pair of safety glasses will protect your eyes from debris, while gloves can help maintain cleanliness and provide grip when handling components. It is also advisable to have a workbench mat or tarp to keep your workspace organized and clean. Finally, ensuring your work area is well-lit will help you see clearly when working on your vehicle. By gathering the correct tools and materials ahead of time, you can make the brake pad replacement process smoother and safer, paving the way for an efficiency-driven experience.

Safety Precautions Before Starting the Process

When undertaking the task of changing brake pads on your car, prioritizing safety should be your foremost consideration. Engaging the parking brake is critical before beginning any maintenance work on your vehicle. This precaution prevents the car from rolling unexpectedly, which can lead to serious injury or damage. Additionally, it is prudent to place wheel chocks behind the rear tires, especially if you are working on the front brakes, to provide extra security.

Wearing appropriate safety gear during the brake pad replacement process is another essential measure. Upon initiating this task, individuals should don protective eyewear and gloves to guard against debris and sharp objects, which could cause injury. Wearing a pair of sturdy work gloves also ensures a better grip when handling tools and components, enhancing your overall control and safety. Furthermore, sturdy footwear is recommended to protect your feet from falling objects, heavy tools, or any other unforeseen hazards.

Another crucial consideration is ensuring that the vehicle is stationed on a stable, flat surface. Working on an incline or uneven ground could lead to slips or falls, so it is advisable to find a secure location, such as a driveway or garage. It’s also wise to avoid performing this task in inclement weather conditions, as wet or slippery surfaces can increase the risk of accidents. Before starting the replacement, confirm that the tools and parts needed are readily accessible, allowing for a seamless and efficient workflow.

By taking these safety precautions into account, individuals can create a working environment that significantly reduces risks associated with car maintenance. Safe practices not only protect the individual but also contribute toward a more efficient brake pad replacement process.

Step-by-Step Process to Remove Old Brake Pads

Changing brake pads is a crucial maintenance task that can enhance your vehicle’s performance and safety. The following guide outlines a systematic approach to removing old brake pads safely and effectively.

First, ensure the car is parked on a level surface and the engine is turned off. Engage the parking brake to prevent any movement. Begin by gathering the necessary tools, which typically include a jack, jack stands, a lug wrench, and a C-clamp or brake caliper tool.

Next, lift the vehicle using the jack. Place the jack securely under the manufacturer’s recommended lifting points, and raise the car until the wheels are off the ground. Once elevated, position jack stands beneath the car to provide additional support, ensuring safety during the entire process.

With the vehicle securely raised, it is time to remove the wheel. Use the lug wrench to loosen the lug nuts by turning them counterclockwise. Remove the lug nuts and take off the wheel, exposing the brake assembly. Be cautious with the heavier components and place the wheel in a safe location.

Now, locate the brake caliper, which houses the brake pads. To access the old pads, you will need to unbolt the caliper. Typically, there are two bolts securing the caliper to its bracket. Use the appropriate socket to remove these bolts, and carefully slide the caliper off the rotor. Support the caliper with a bungee cord or hang it to avoid putting stress on the brake line.

With the caliper removed, you can now see the brake pads. They are usually held in place by retaining clips or pins. Remove these components to free the old brake pads from the bracket. Carefully pull the pads away from the rotor, noting the orientation, as this will assist in correctly installing the new pads later on.

Installing New Brake Pads: A Detailed Guide

When it comes to maintaining your vehicle, one of the most critical components is the brake system. Installing new brake pads is a manageable task that can be undertaken with the right tools and a bit of preparation. The process begins by ensuring that you have all the necessary materials on hand, including new brake pads, brake grease, a c-clamp, and a lug wrench. Before starting the installation, consult your vehicle’s manual for specific details about your model, as brake pad types and sizes can vary significantly.

Begin the installation by safely lifting the car with a jack and securing it on jack stands. Remove the wheel to expose the brake assembly. Next, inspect the caliper, as it holds the pads in place. Carefully loosen the caliper bolts, then slide the caliper off the rotor. Pay attention to how the old pads are positioned, as the new pads will need to replicate this setup.

Before placing the new brake pads, it is essential to clean the caliper and rotor surfaces to ensure proper adhesion and performance. Apply a thin layer of brake grease on the contact points of the pads and caliper, as this will help reduce noise and friction when the brakes are engaged. Ensure that the brake pads fit snugly in the caliper bracket, avoiding any movement during operation. If your vehicle is equipped with shims or clips, ensure they are correctly installed as per the manufacturer’s specifications.

Once the new brake pads are in place, reposition the caliper over the new pads and reattach it with the caliper bolts. Before lowering the vehicle back to the ground, pump the brake pedal a few times to ensure that the pads set properly against the rotor. Finally, replace the wheel, tighten the lug nuts securely, and lower your vehicle. Your new brake pads are now installed, ready to provide optimal stopping performance and ensuring your safety on the road.

Testing Your Brakes After Replacement

Once you have successfully installed new brake pads on your vehicle, it is essential to conduct a thorough testing of the braking system to ensure that everything is functioning as expected. Proper testing not only confirms that the new brake pads are correctly seated but also assures the driver of safe operation in future drives.

Start your testing procedure in a safe, open location away from traffic, such as an empty parking lot. Before moving the vehicle, gently pump the brake pedal a few times. This action helps to seat the brake pads against the rotors, ensuring they are aligned properly. You might notice that the pedal feels spongy at first; this is common and typically resolves itself after a few pumps.

Next, with the vehicle in gear and at a low speed, gradually apply the brakes to assess their responsiveness. Pay attention to how the brakes feel; they should provide consistent stopping power without any squeaking or grinding noises. If you hear unusual sounds, it may indicate that the pads are not installed correctly or that there might be an issue requiring further investigation.

It is also advisable to perform a series of moderate-speed stops. This allows you to gauge how effectively the new brake pads are engaging. While doing so, maintain a steady pressure on the brake pedal and assess if the vehicle stops smoothly without pulling to one side or another—a common sign of uneven pad wear or misalignment.

Lastly, after several rounds of testing, check the brake fluid level to ensure it remains adequate. Should any issues arise during your test drives, such as brake fading or inconsistent performance, it is prudent to revisit your installation process or consult a professional mechanic for further evaluation. Testing your brakes thoroughly after replacement is integral to maintaining vehicle safety and performance.

Maintenance Tips to Extend Brake Pad Life

To maximize the longevity of your brake pads, it is crucial to adopt specific maintenance practices and driving habits. One of the most effective strategies is to avoid aggressive driving. Rapid acceleration and sudden stops can contribute to excessive wear on brake pads, leading to premature replacement. Instead, practice smooth and gradual acceleration, as well as gentle braking, to minimize strain on your brake system.

Regular inspections of your brake system are also essential in extending the life of your brake pads. Schedule check-ups at least once a year or every 10,000 miles, whichever comes first. During these inspections, a professional mechanic can assess the condition of the brake pads, rotors, and the entire braking system. This proactive approach ensures potential issues are identified before they escalate, reducing the need for more costly repairs.

Another important factor is the quality of the brake pads used in your vehicle. Opting for high-quality brake pads designed for your specific make and model can lead to better performance and increased lifespan. While these premium options may cost more initially, they often offer improved heat dissipation and better resistance to wear, thereby reducing the frequency of replacements. Additionally, using brake pads that align with your driving style and the type of vehicle you own can also enhance performance and longevity.

It’s also wise to remain aware of warning signs indicating your brake pads may need replacement, such as squeaking or grinding noises, responding less, or vibrations during braking. If you notice these signs, it is advisable to consult a professional for an evaluation. Ignoring these indicators can lead to more significant damage to the brake system and potentially compromise safety.

By following these maintenance tips, car owners can significantly improve the lifespan of their brake pads, ensuring a safer and more cost-effective driving experience.